This is a transcript of a Rayovac webinar on AudiologyOnline. Download supplemental course materials: slides and reference guide.

Kevin Kouba: Today we are going to talk about some important things for you to know to ensure patient satisfaction with hearing aid batteries. After completing this training, you should be able to understand how a zinc-air hearing aid battery functions, explain factors that affect the life of a zinc-air battery, and most importantly, counsel with your patients on things like battery life expectations, proper care and use of hearing aid batteries, and lastly, determine and resolve when a patient has a battery issue versus an issue with their hearing instrument.

Zinc-air Technology

What is zinc-air technology? As the name implies, zinc-air technology uses oxygen from the atmosphere as an active ingredient. This technology is used almost exclusively in hearing aid battery applications. Since that is the case, it is very important for us to have relationships with the hearing instrument manufacturers to ensure that batteries work properly in their devices and vice-versa. There are some other unique aspects that make zinc-air batteries different from other types of batteries.

Some of the more noticeable ones would be the need for a tab or sticker to seal the vent holes in the battery and prevent dry out. Another is that zinc-air batteries are best used soon and consistently after activation, because the battery begins to discharge as soon as that tab is removed; it is impossible to stop that discharge from occurring once you have removed that tab. Battery performance, and ultimately hearing aid performance, can be sensitive to the environment, whether we are talking about temperature or the amount of moisture in the air, known as humidity.

Why does zinc-air chemistry make sense for hearing aid batteries? Most importantly, zinc-air batteries provide longer life and more energy than any other type of battery or cell system. That is especially important when you are talking about very small instruments like hearing aids. Other products that use button cell batteries, such as watches, do not require the same sort of power that hearing devices do. Zinc-air batteries have a much higher capacity-to-volume ratio, sometimes known as energy density, than other types of batteries.

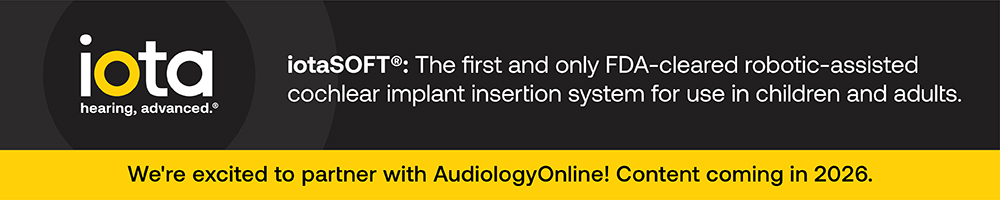

Virtually all battery or cell systems store their positive and negative reactive components inside the cell. However, since zinc-air uses oxygen from the atmosphere as one of its reactants, it frees a large amount of internal space to allow for more zinc (Figure 1). The more zinc available in the battery means longer life.

Figure 1. Comparison of the amount of zinc contained in button batteries versus hearing aid batteries.

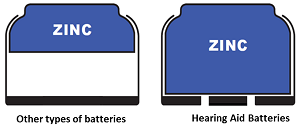

As I indicated earlier, removing the sticky tab activates the battery as air enters through the holes (Figure 2). After the tab is removed, the battery literally requires a moment to “catch its breath.” As air starts to enter the battery, it becomes able to be activated. We always recommend that you let the battery sit for a full minute before you insert it into the device and shut the door. That is important because it allows the voltage in the battery to rise and ensure that you will not have start-up problems with the hearing aid.

Figure 2. Schematic of oxygen activation of a zinc-air battery.

Voltage is another thing that should be explained. Although the package of most batteries will state 1.45 volts, the fact of the matter is that batteries that are still tabbed on the shelf will measure anywhere from 1.1 to 1.3 volts if you were to test them with a volt meter. After you take the tab off, the voltage will rise enough to power a hearing aid within one minute, but the entire cell could take as long as 24 hours to rise to the maximum 1.45 volts. Un-tabbed voltage after a maximum of one day is 1.45 volts. The important thing to know is that the hearing aid does not require 1.45 volts to operate.

Evolution

How has battery chemistry evolved over time? The first zinc-air hearing aid battery was introduced in 1977. At that time, mercury was used as an active ingredient in the cell. We will talk about how that has changed over time. In 1986, Rayovac introduced the size 10 hearing aid battery, enabling hearing instruments to become much smaller, as there was now a smaller battery that could power them and fit inside.

In 1996, legal requirements changed battery design and production, and the Mercury-Containing and Rechargeable Battery Management Act was enacted, which banned the use of mercury in alkaline batteries and tried to limit the amount of mercury that could be used in button-cell batteries. The movement went on to remove mercury from hearing aid batteries. In 2006, the National Electrical Manufacturer’s Association (NEMA) took a stance and asked all battery companies to remove mercury from hearing aid batteries by June 30, 2011. Most of the leading battery manufacturers voluntarily agreed, including Rayovac. In 2010, Rayovac introduced their first mercury-free hearing aid battery with the same performance as the previous mercury-containing product.

In 2011, the NEMA position took effect, and, at the same time, the first mercury-free cochlear battery was introduced by Rayovac. Since that time, many states have passed their own legislation requiring hearing aid batteries to be mercury-free. There are now six states that ban the sale, offer to sell, or distribution for promotional purposes of any mercury-containing hearing aid batteries.

There is also pending legislation in a number of geographies. In 2012, federal legislation was purposed that would ban the use of mercury in hearing aid batteries in all 50 states.

Tips for Consulting Patients about Battery Life

Communicating with patients on how to correctly manage their expectations on battery life is an important topic. We get many questions about how long the batteries should last. The truth is that there is not one answer that works for every patient. That is because every person is unique when it comes to the degree of hearing loss, their personal listening environments, and how they use the device. All of these factors combined make a person’s hearing loss unique as their fingerprint. Therefore, no one patient is going to have exactly the same battery life as another. We want to educate you, your staff, and your patients on these factors to help them better understand the reason that there are differences in hearing aid battery life.

The first factor that affects battery life is an individual’s hearing loss. As the severity of hearing loss increases, the hearing instrument is required to amplify sounds more, which increases the amount of current that the hearing instrument requires, which logically reduces battery life. And individual’s severity of hearing loss is a large factor.

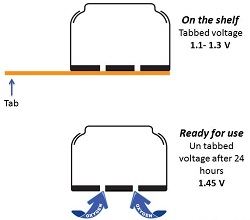

Another factor is the battery size. We all know the hearing aid market is shifting towards smaller devices. Logically, the smaller the device, the smaller the battery needs to be. As a battery’s physical size decreases, so does the amount of the zinc that can fit inside the battery. We talked earlier about how important the amount of zinc is. The more zinc in the battery, the longer it will last. For illustration purposes, look at the size difference between a size 10 and a size 675 battery (Figure 3). The 675 can hold more zinc and therefore, lasts longer.

Figure 3. Comparison of zinc contained in a size 10 battery versus a size 675 battery.

Another factor that affects battery life is an individual’s hearing aid usage. How many days a week do they wear their hearing aid? We all know some patients wear their hearing aid religiously every day, yet we know others at the opposite end of the spectrum who might only wear their hearing aid on Sunday morning for an hour. People love to talk about getting so many days’ worth of life out of their batteries. Yet to one person, a day is 8 hours and to another person a day is 16 hours.

Here is an example to illustrate why it is important to get an accurate estimate of a person’s usage to understand how long a battery can last. Let’s say Person A gets five days out of their hearing aid battery and Person B gets seven days. Which hearing aid battery lasts longer? To answer that correctly, you need more information. Assume Person A wears their hearing aid 16 hours a day, but Person B only wears it 8 hours a day. The correct answer then would be Person A, because they got 80 hours out of their battery versus 56 hours for Person B. Getting enough information is important. When talking to patients about battery life, use a common measurement of time, such as hours instead of days, to get an accurate picture of battery life.

Instrument Differences

There is definitely a fundamental shift in hearing devices that is driving the battery market. Some of the changes in the device market are shifts to completely digital, more advanced processing features, and more available accessories, including wireless options. This shift in the market leads to more demanding power usage, which translates to fewer hours of battery life. There is also a certain lifestyle dependence that people are now able to take advantage of. These include things like using hearing instruments and accessories to watch TV, to use cellphones and listen to personal music.

When using standard features in today’s digital instruments, you can see current demand increasing up to 300%. There is an amount of electrical current that the instrument demands. When you add in digital features of today’s instruments, it may reduce battery life by 20%. The premium features like looping, FM, tinnitus programs, wireless and Bluetooth features, and of some settings intended to give the patient a better a better experience, like a low battery warning, all require additional energy. When in use, they can increase the current draw up to 300%, further reducing battery life.

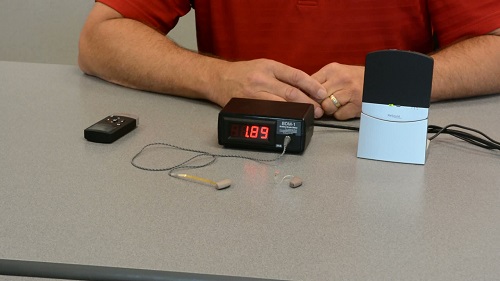

Now we are going to watch as Denis Carpenter, who is the director of zinc-air product technology at Rayovac, demonstrates the effect of some of the new hearing aid technologies on batteries.

Environmental Factors

The environment is another key factor. Zinc-air cells are sensitive to environmental conditions, such as temperature and the presence or absence of humidity. For example, if you live in a very dry climate or use your furnace in the winter, the batteries can dry out more quickly. The opposite effect could also happen with high humidity. Batteries will absorb moisture through the holes in the battery, which can shorten life and lead to leakage.

Temperature

As temperature is reduced, hearing aid battery voltage is lowered, reaching its endpoint earlier; in other words, it reduces battery life. This could be an issue if you are working outside in the winter or if you happen to have a patient who works in refrigeration all day. They can see shortened battery life.

Altitude

As altitude increases, the percentage of oxygen in the air is reduced. If you are up in the mountains, there is less oxygen in the air, and that will potentially cause the battery to reach its endpoint earlier. If you combine altitude with low temperature, it can be even more extreme.

The combination of these factors produces a large range of battery life expectancies. In a recent market survey we performed, device users were asked how long their hearing aid batteries last. For size 10 batteries, people were experiencing anywhere from 3 to 10 days; for size 312, from 3 to 12 days; for size 13, from 6 to 14 days; for size 675, from 9 to 20 days. This represents 80% of those who surveyed. The remaining 20% had experiences that were outside of this range. This illustrates how difficult it is to take a guess on how long battery life will be for a patient. This wide range shows why we recommend you not give your patients specific life expectancy numbers, because it ultimately sets the patient up with expectations that might not be met. They may return to you with complaints that their batteries are draining quickly or that the hearing aid is not working as expected.

Figure 4 is an illustration of what a battery-life chart those looked like in the past. The battery sizes are listed across the top of the page and the current draws or milliamp/hour draws are listed down the left-hand side of the page. We do not recommend that these types of charts be used to provide guidance on battery life, and I will tell you why. Two factors are calculated to reach the estimated battery life, and both of these can be exaggerated. The first one is the battery manufacturer’s capacity ratings, or the milliamp/hour rating. These ratings are generally set with a brand new product, which is not always the case in the market, particularly with imported products that can take longer to reach the shelves. Low-drain application is the other way these are calculated, which creates the best-case scenario or an overestimated value. Secondly, the American National Standards Institute (ANSI) for battery current drain uses testing applied to batteries with a hearing aid test in a test position, not in a normal hearing application. This creates an underestimated value.

Figure 4. Example of previously-distributed hearing aid battery life chart.

The bottom line is to avoid giving a standard battery life estimate to patients. You need to work with them individually to determine battery life, and the best way to do this is to have them track their individual battery performance over time. Ask them to write down when they put a battery in and when they take it out. Do not do this with just one battery; use an entire package or two to see how and where they are using their batteries over time. After this is done, the patient will have a good sense of how long their battery should last.

Now I would like to introduce Ann Rule, who is our Director of Marketing. She will take you through the next portion of our presentation.

Steps to Ensure a Good Battery Experience

Ann Rule: I want to talk more about steps to ensure a good battery experience with your patient. First, we want to talk about getting your patient off to a good start with their new hearing instrument and how important that can be.

The first step is to always use a fresh hearing aid battery when you are programming the instrument. The programming cycle of many of the hearing instruments on the market today can put high demands on the battery and reduce the battery life. In fact, we have seen some instruments that can use up the entire battery during a programming cycle. Therefore, we want to make sure that when you are done programming that you do put in a fresh battery. You are going to use a fresh battery when you start the programming process and again when you complete it. Make sure that the patient leaves with a fresh battery with the full life expectancy available.

As you send them home for the first time, remind them of some very basic hearing aid battery care tips. Number one, store the hearing aid batteries at room temperature. Avoid extreme temperatures. Do not store them in the glove compartment of the car, in a sun room, or the refrigerator. As you heard earlier, these extreme temperatures can affect battery life.

In addition to that, we want to make sure the hearing aid batteries are stored in the original packing or in a battery caddy. One of the reasons for that is that metal objects like coins and keys can short out the batteries. It is not a good idea, even with the tab on, to have batteries loose in anyone’s pocket or purse, and we do not want the batteries to touch each other during storage. It is important to keep them in the original package or in a battery caddy.

Furthermore, we always want to make sure that discarded batteries are stored in places that cannot be reached by infants or children. That is something that is true with any small coin or button cell, but is extremely important with this type of product because we know many grandparents are using these devices and small children could be around at any time.

As Kevin mentioned, we have done research on many different things regarding hearing aid patients. One of the things we know is that the first place they go if they have questions about hearing aid batteries is their hearing professional. We want to make sure that you are well-equipped to answer those questions.

Troubleshooting Battery Issues

Whether you and your practice are new to offering hearing aid batteries or whether you have been carrying them for years, it is important to know how to handle patients who have battery issues. Let me walk you through a short protocol to determine if batteries are part of a patient’s device issues.

Ask Questions

It is most important is to ask questions. We do not want to assume anything. It is human nature to try to come up with an answer to someone’s question or problem as promptly as possible. When you have a patient who is at your door with what you may think is a battery issue, you want to fix the problem quickly. As a battery manufacturer, we get contact back not only from hearing professionals, but also from consumers stating that what we believed was the issue when we first start talking to the patient many times turns out to not be the issue at the end. We need to ask questions and not assume anything.

Listening

Listening carefully goes hand-in-hand with asking questions. The smallest comment can lead you to an answer. We had customer call our consumer hotline a few weeks ago, stating he had problems with short or no battery life. Through a series of questions, we found out that this consumer had been storing batteries in a cup in her bathroom. The batteries were shorting each other out in this cup intermittently. It was not every battery that had an issue, but we were able to determine how the battery was stored by asking questions and listening for remarks in the consumer’s answers. Furthermore, we were able to educate that consumer and also find out that there was no real battery issue; it was more of a battery handling issue.

Use Your Resources

Lastly, use your resources. One objective of this course is to bring everyone up to speed on some of the contemporary battery issues, but also on some of the fundamentals. We understand that batteries are a small part of your patient care, and many people in your office may not be accustomed to answering battery questions on a regular basis. You cannot be expected to remember every detail, and we understand that. Therefore, we can be a resource to you when you need us. Our Web site has different materials available for you to download to provide to your patients. Your own Web site could be a great resource for patients as well. If you have navigated through some of the things I will talk about today and you cannot solve the battery issue, please rely upon us and your ProLine product consultant to help.

Battery Complaints

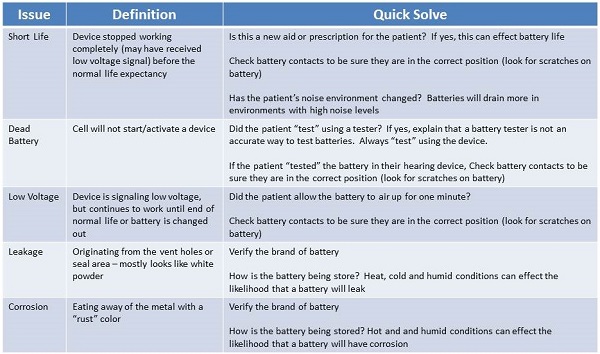

In troubleshooting the type of battery complaint, we can put the different types of complaints into five different categories to help decipher what the true issue is and, therefore, provide a solution.

Short Life

The first complaint is short life. We describe short life as the situation where the device has stopped working completely before the patient feels that that life expectancy of the battery is done. A patient may have received a low battery signal or is experiencing shorter life than what they typically expect.

Dead Cell

A dead cell is a fresh battery that will not start or activate the device when new out of the package.

Early Low-Battery Tone

Although it ties into short battery life a bit, we feel a different category is early low-battery tone. This is where the device is signaling a low-battery tone, but it continues to work through the normal life expectancy of that battery or when it is changed out. For example, a patient may say that he usually gets five days from his battery. He now says that the low-battery tone starts signaling at three days, but he still gets that five days of battery life. It is still amazing to me that patients will continue to use the battery until it dies, even though they are having to tolerate this low-battery tone. This is a separate issue, but something we definitely see.

Leakage

The next category I want to talk about is leakage. We previously mentioned a few instances where we see this with extreme temperatures. Most of the time, leakage looks like a white powder coming out of the air vent holes or the seal area where the grommet is in the cell. That powder is dried electrolyte that has come out of the cell through those holes.

Corrosion

Lastly, corrosion is a bit different from leakage. Corrosion is more of a rust color and is literally the cell being eaten away. Although leakage and corrosion sound similar, there are different reasons behind their causes. Therefore, it is very important that we understand which one it is.

Troubleshooting Battery Complaints

We are going to do a troubleshooting exercise for each one of those categories.

Short Battery Life

Short life is where the device has stopped working completely before the normal life expectancy. The first thing we need to decide is if this is a new hearing aid. If a patient has recently received a new device, they may be used to receiving a certain amount of battery life from their previous aid, but may not have understood that a new aid could potentially have other features or circuitry that would drain the battery more quickly their previous device. If the patient has, in fact, received a new aid, we want to talk to them about battery life expectancy. No two aids are alike. Talk to them about benchmarking that performance. Give them a pack of batteries and have them keep track of how long each one lasts so they understand that this device will have a different battery life expectancy than the previous aid.

If the patient has had this aid for two years and nothing has changed, we want to talk about any recent setting or prescription changes. Has something been done to that device that makes it different from the last time they used a battery? If that is the case, advise them that battery life can change with different programming. We want to make sure that we educate them that although it is the same device, there are some things that have changed that would change the battery life.

If the settings have not changed, we want to look at the battery cell itself and look to see if there are scratches from the contacts. If you have been in practice for a while, you may have seen small scratches on the battery. The contacts within the aid have to scratch the surface of the cell to make a good contact and work well. If you do not see those scratches on the contacts, we would want you to examine the size of the battery and look for potential swelling. The battery compartment, as you know, is very tight. Although there is a standard in battery height, battery heights can vary by manufacturer. We want to make sure that those contacts have not been expanded due to swelling of a battery or simply a different type of battery being put in there. Please check the contacts and adjust them to make sure they are making contact with that battery. If there is an issue with the contacts, handle that with repair, but understand that truly is not a battery issue.

If there are scratches on the battery and we believe there is good contact, we want to have the discussion with the patient about their noise environment. Has their noise environment changed? Did they recently go to a concert? Have they been on vacation? Did they get a new job? Are they in a different place of employment? We also know that fluctuating sound environments or spending more time in demanding environments can also change the battery requirements.

If the listening conditions have not changed, we want to talk to them about the weather conditions. Has it been very hot or cold recently? Ask how they are storing the batteries. If there have been any humidity changes, for example, the battery can take up moisture which can shorten the battery life. Dryness can shorten the battery life because the battery is giving up some of the moisture that it needs to function properly, as well.

If we have gone through this series of questions and have not come to any conclusions, then we to ask them about getting battery samples back. If the patient has the pack of batteries with them or a single battery that had issues, please return that battery package or battery cell to the manufacturer. It is critical for us to do an investigation so that we have that information. We know that our patients do not always have the samples available. What we like to do then is have you send them away with a fresh battery. Have them try it, but tell them to hang on to any type of battery that they may have an issue with so that we can look into it and do some problem solving.

Dead Battery

Now I want to talk about a similar conversation when the patient feels that they have a dead battery. Again, this means the cells is not going to activate or start the device. The number one thing we ask consumers is, “Did you use a battery tester to look at the power or did you put it in the hearing aid? If they used a tester, which we do find happens, we want to understand if the battery was un-tabbed when it was tested. Remember that a tabbed battery is going to test with lower voltage than an un-tabbed battery. Explain that they should un-tab the battery, wait a minute for it to air up and then re-test the battery. If the battery was un-tabbed, encourage them to put the hearing aid battery in to the hearing aid and see how it works.

This is another patient education opportunity. We find that people think they are doing the right thing by testing the batteries in a tester, but the device is the best way to test that battery. If they did not use a tester and are saying that the battery does not start or activate the device, have them tell you exactly what they did, and try to understand if they truly put it in the device. Educate them that putting the battery in the device is how we test the hearing aid battery.

If they are still not able to activate the device with the battery, look at it again to see if it has contact scratches. We need to examine the contacts like we did when we were talking about short battery life. If the battery does not have scratches, look again at the contacts to make sure they are in proper form.

If you notice that the battery does have scratches, take this as a sign to talk to them about how the batteries were stored. Are they stored correctly? This is also a great education opportunity for that patient. If they are stored correctly and we have talked about all the other scenarios and options, we are back at the sample situation. We want to have that battery or package that they are talking about. Return that to the manufacturer for further investigation. We at Rayovac take that very seriously, and we process those through our quality group at our manufacturing facility and do our due diligence once the reports come back. Let your patients know that troublesome batteries are something they should hang on to and bring back to you. Always send them away with a fresh battery so that they have a good experience.

Low Voltage

A low voltage issue is when a hearing device’s low battery indicator is triggering, but the instrument continues to work. I think this is becoming a more important scenario as more hearing aid accessories are introduced. As we know, accessories increase current demand, and if you have users that are intermittently using some of these accessories, they may see this more than other patients.

Ask first if the battery is airing up for one full minute. This, too, has become more important as devices have become more demanding. A fresh battery needs a full minute to air up so that it can reach a voltage level that is optimal for best battery performance in the device. If your patient is not doing that, it is an easy educational fix. We offer what we call air up cards, and we recommend you give one to all new hearing aid wearers so that they understand the importance of giving the battery that air up time. That can be a very simple solution to an issue that they may be having.

If they did allow the battery to air up for one minute, we again go back to the train of thinking we had earlier. Is this a new aid? Are there differences with this aid that may affect life expectancy or does it have accessories that may change that voltage level? If it is a new aid, check for those battery scratches to make sure that the contacts are in working order and that the battery is fitting properly to achieve that full current drain.

If the battery has scratches or is not a new aid, have their listening environments changed? Depending on how that aid is programmed, the voltage can fluctuate and we want to understand that so we know what the expectation is. If that environment has not changed, we are back to needing the sample batteries. Once again, send those into the manufacturer and have them take a look. If the patient does not have the batteries, educate them and then send them away with a fresh battery.

Leakage

It may be important to try to understand what brand of battery you are dealing with when there is leakage. We know from research that patients may buy batteries in different channels. When they come to your office for an adjustment or a new hearing aid, they will buy batteries from you, but they may stop for a prescription refill at the drug store on the way home and pick up a pack of batteries. Do not always assume that the battery they are using in the device is a battery that you have sold or given them. You have to look at this carefully. Here are some tips on how you can verify that.

You can clearly see the battery in Figure 5 has a blue grommet. Looking at the grommet is one way that we know that we can identify the brand of battery. Batteries manufactured by Varta Micropower are usually under the PowerOne brand in the professional channel or the Duracell brand at retail and have a blue grommet. Most other manufacturers, including Rayovac, have black or clear grommets that look black. If it turns out that your patient is purchasing batteries at retail, this may be an opportunity for you to get them to come back and buy batteries from you. You may want to talk to them about the freshness of batteries on the retail shelf, or the lack of freshness. Because we are a consumer products company, we know that the products out at retail are not as fresh as the batteries coming through you, the hearing professional. We bring this up because it is an opportunity for you to bring that battery business back into your office where they can purchase the freshest batteries available.

Figure 5. Example of corroded battery; the color of grommet, blue in this case, can help indicate the brand of battery.

If we know the brand of battery, we also want to find out whether or not the batteries were stored correctly and educate the patients on the importance of keeping batteries in optimal environments. Batteries can swell from moisture and leakage, so also check the contacts and potentially adjust those if the battery has swollen in addition to leaking.

If there are leakage problems, the manufacturer will want to know about it, so this is a case where you would also send samples back if you have them. Quite honestly, we see very few leakage issues. To me, if a patient is having that type of problem, it could very likely be in the way that the batteries are stored or some other mishandling.

Corrosion

The last category I will address is corrosion, which is the eating away of the metal with a rust colored substance. Figure 6 shows an example of a rusting battery. You can see the eating away of the can from the side view, and you can see the rust very well from the top view. You can visually tell that this is different from leakage.

Figure 6. Batteries with corrosion.

Were the batteries stored correctly? Moisture from refrigeration and perspiration can cause this kind of corrosion. In the summer months, droplets of sweat from the hair or skin can go right into the hearing aid, especially in the cases of behind-the-ear hearing aids. Some of the scenarios should be discussed so you can determine the root cause of the rust. One point I do want to make is that Rayovac uses a stainless steel casing on hearing aid batteries, which is resistant to rust.

If the batteries are stored correctly and there is rusting from excessive perspiration, hopefully you are talking to them about dry aid kits to solve that. If the batteries were stored correctly and they have a clear understanding of that, we do want to get those samples, again. As a manufacturer, we take those very seriously and we want to make sure that we understand the root cause. If the patient does not have a sample, we would treat this patient the exact same way as we have handled the previous cases- we give them a new battery and make sure that they walk away with the best experience.

Figure 7 is a quick reference for you to use when troubleshooting hearing aid battery issues. This reference is available to you on our Web site (thepowerofhearing.com) under the Download section. It may be a good idea to save this and provide it to other professionals in your office as a talking point or quick reference should you need it.

Figure 7. Quick reference sheet for hearing aid battery troubleshooting. View larger version (pdf).

Summary

Kevin Kouba: Now that you have completed this training, we want to recap. We hope you will be able to understand how a zinc-air battery functions. It was not our intent today to turn you into a zinc-air scientist, but rather to give you a good working knowledge of how a zinc-air battery functions. The information presented should allow you to be able to explain the factors that affect the life of a zinc-air battery and consult with your patients on battery life expectations, be able to educate your patients on the proper care and use of hearing aid batteries in their instruments, and determine when a patient has a battery issue versus an issue with their hearing instrument. Hopefully today’s tools and information will allow you to be able to resolve the situation.

Rayovac offers many more materials, information, and even personal consultation, as necessary, with us or our technology group to help you, your staff, and your patients. Please contact Rayovac’s ProLine product consultants at the 800-356-7422, or visit our Web site at thepowerofhearing.com for more information.

Cite this content as:

Rule, A., and Kouba, K. (2013, December). Rayovac hearing aid batteries – important things to know to ensure patient satisfaction. AudiologyOnline, Article 12293. Retrieved from: https://www.audiologyonline.com