Learning Outcomes

After this course, participants will be able to:

- Describe appropriate impression quality for earmolds.

- Describe appropriate earmold materials.

- Explain how to select an appropriate earmold style.

Introduction

An earmold is a custom fabricated device that channels the sound reproduced by a hearing aid through the ear canal. Since this is custom-made, we need to assess certain qualities by achieving specific objectives. There are four key factors to achieve a custom earmolds' objectives of delivering sound through the ear canal: impression quality, earmold material selection, style selection, and earmold acoustics. We will cover the first three factors during this course, as earmold acoustics is perhaps an intermediate level course which would require a class of its own. What are these objectives and how do they compare to universal domes? The first objective would be to provide a satisfactory and proper acoustic seal. Secondly, we need to have good retention on the pinna. Another goal is to acoustically modify the signal produced by the hearing aid. The comfort factor is critical because most users will wear their devices all day long. Finally, it has to have an acceptable appearance. Many patients do not like to expose their hearing impairment, so aesthetics is vital. These objectives: seal, retention, acoustics, comfort, and aesthetics are advantages of custom earmolds over universal ear domes.

Key Factor 1: Ear Impressions

We start the process with an ear impression which involves specific requirements. By my experience, 50% of the success of a custom earmold is dependent on the quality of the impression. If we do not have a good impression, we will have a tough time producing a precise custom earmold. Most fit issues with earmolds can be eliminated by taking an accurate ear impression. Those issues, most commonly are seal, comfort, and retention.

Impression Taking Process

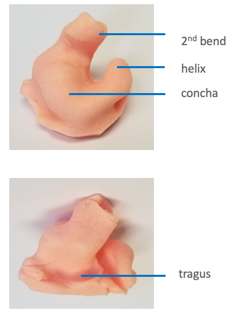

When you take an impression, never rush the process. Investing an extra minute may yield a reliable and perfect result. Always keep the nozzle tip in the material throughout the process and never remove the nozzle from the material. As a quick review, the order of taking impressions begins with inserting the nozzle into the canal. Then as you fill the material and pull the nozzle out of the ear, make sure that you cover the entire canal, and then go over the tragus. Capturing the whole tragus area is critical. Once the tragus is filled, you can move the nozzle towards the concha. Once the concha is filled, finish with the helix dip. It is important on how a clinician fills this section with the impression material. The first area of concern is canal length. The canal length has to be up to the second bend of the ear canal. The concha bowl (i.e., cavum), crus of helix, and cymba need to be adequately defined and filled. The tip of the Helix is also an important area because this provides excellent retention. We do not use the entire tragus, but for some production concerns, we would like to have at least minimum of 3/4 of the tragal cartilage.

Figure 1. Landmarks of an ear impression.

Key Factor 2: Earmold Material Selection

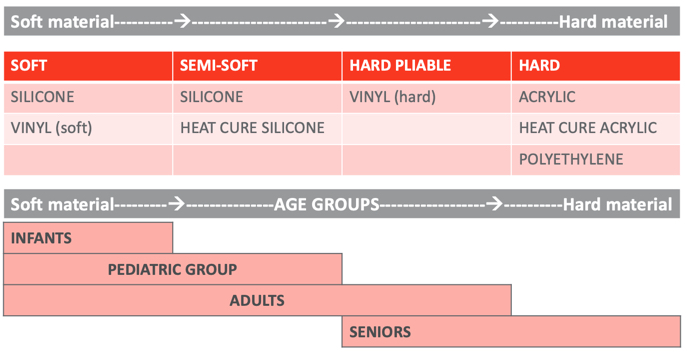

Now we will discuss details for selecting the appropriate earmold material for each patient. Let's first consider the retention of an earmold. Our ears grow during the entire lifetime, and they never stop growing. As they grow, the pinna becomes softer, and retention issues may arise. Soft materials are recommended for a hard pinna (e.g., pediatrics) and harder materials are recommended for a soft pinna (e.g., elderly, seniors). We recommend the softest materials for infants. For adults (i.e., ages 20-60), a variety of earmold materials are appropriate for this age group. Seniors, generally do well with harder materials. Figure 2 shows the most common material types available in our industry. When fitting a custom earmold on a pediatric patient, we need to consider certain factors: hygiene, activities, insertion, and growth. Consider selecting a material which is easy to clean (e.g., antibacterial materials). We recommend the polyethylene material, which is a very hard material when none of the soft materials can be used because of allergic reactions. Typically polyethylene is chosen as a last resort for its superior hypoallergenic properties. Keep in mind the child's activities and comfort during extended use. Except for the summertime when schools are not in session, children tend to wear their hearing aids all day long. Insertion may be an issue for pediatrics especially if have sharp bends to the ear canals. In that case, perhaps you can use a harder material and not the softest. Other factors to improve ease of insertion is selecting a matte or silky surface. Harder materials are not as pliable and will not be comfortable in the child's ear as they grow. This is why we recommend softer materials for pediatrics. Children are very active and if their earmold is damaged a soft material will be safer in preventing further injury.

Figure 2. Earmold Materials.

Soft Vinyl

Soft vinyl is recommended for infants because it is soft and comfortable to insert. This material can be modified in your office if you have the right tools. More importantly, this material can be cemented, and you do not need to use a tubing anchor into the earmold. When we are dealing with a tiny ear canal, a tubing anchor may require a larger space. There are some disadvantages of soft vinyl materials, as they are notorious to shrinkage. We do not recommend an earmold made of soft vinyl for more than 12 months.

Silicones

Silicones are the most popular material because of its versatility and desirable qualities. Custom earmolds made of silicone are comfortable, durable, and do not shrink. During the production process, the material sets and is cured. Silicones are known as hypoallergenic materials (e.g., platinum cure, heat cure). Unfortunately, we cannot glue or cement the tubing into the earmold. We have to use a tubing anchor or tube lock.

Platinum cure. This is the most popular silicone type. The hardness can vary anywhere from Shore A 25 to Shore A 60. In our industry, there are approximately ten different materials available in this category and multiple color options. The surface can be either glossy or matte and are known for their longevity.

Heat cure. Heat cure silicone is a better choice than platinum cure when high precision is needed for intricate details. This is very important when it comes to power BTE hearing aids. Keep in mind that platinum cure silicones are not modifiable with simple office tools. Thus, heat cure silicones may be a better choice. Heat cure silicones are typically semi-soft, so do not expect to receive a super-soft material. Because of its high definition surface properties, it provides a superior seal over other silicone materials.

Hard Vinyl

This material is quite hard but becomes pliable when in contact with body heat. It takes approximately five minutes to become flexible once in contact with heat, otherwise, it's a hard material. Hard vinyl is known for its hypoallergenic properties and can be cemented. Custom earmolds made of hard vinyl are somewhat of a discreet solution. In our experience, this is a prevalent choice for senior citizens, especially when they want a smaller earmold that is less visible.

Acrylic

Custom earmolds made of acrylic materials are hard and hypoallergenic. The tube can be cemented or glued. Typically they're discreet because of its high transparency or translucency. The standard acrylic is a default custom earmold material ordered through hearing aid manufactures, usually for RIC devices. There are two types of acrylic materials. One is a standard acrylic, and the other is a heat-cure acrylic. You cannot tell the difference by just looking at it. The main difference is in regard to patients with allergic reactions you would specify heat-cure acrylic when ordering.

Polyethylene (PE)

I briefly mentioned this material in the pediatrics section. PE is also a hard material and is the most hypoallergenic material in the industry. Tubing will need to be cemented with PE custom earmolds. One issue with this material is that it is only available in opaque beige. Thus, making it an undesirable look and is typically used as a last resort for most of your allergic cases.

Combo Materials

Occasionally, two materials are combined to form the earmold to achieve the best custom earpiece for the patient. Typically, we would start with a hard material for the concha and would use either soft, semi-soft, or sometimes pliable vinyl materials for the canal to provide a stronger seal. For some surgical ears, a hardened concha is used for saccule retention and a soft canal for a stronger seal. An example of when a combo material is beneficial is with a patient who has a profound loss and a straight canal. With a straight canal, it is challenging to retain the earmold. The hard concha material would resolve our retention problem, whereas the soft canal portion will address the seal.

- Acrylic concha with soft vinyl canal

- Acrylic concha with hard vinyl canal

- Acrylic concha with semi-hard (heat cure) silicone

- Semi-soft (heat cure) silicone concha with soft heat cure silicone

Key Factor 3: Earmold Style Selection

Earmolds are available with a wide range of styles to address difficult physical challenges and acoustic requirements. There are two main types of earmold styles: occluding and non-occluding.

Occluding Earmold Styles for BTEs

Occluding earmolds are designed to seal the ear canal completely. This style of earmold is recommended for pediatrics and patients with a severe to profound hearing loss. Generally, all power behind the ear hearing aids will be coupled with an occluding earmold to obtain a good seal.

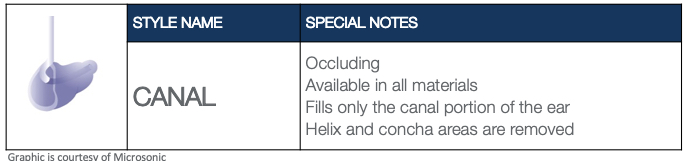

Canal. Among the occluding earmold styles, a canal mold is the most common style because it addresses the very characteristic of an occluding earmold which is sealing the ear canal. It is the least visible style. However, it lacks retention if you have a straight canal. A canal mold retains well if your patient has sharp first and second bends. This style option is available in all materials.

Figure 3. Canal style earmold.

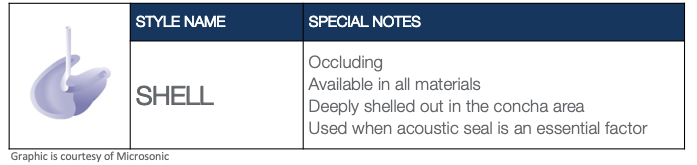

Shell. An alternative to a canal style if you have retention issues is a shell mold. It provides the same seal as a canal and pushes the earmold into the patient's ear. A full shell earmold may not be preferred for cosmetic reasons as it does take up the entire concha bowl. So what do we do if we want to seal the ear canal but retention is an issue?

Figure 4. Shell style earmold.

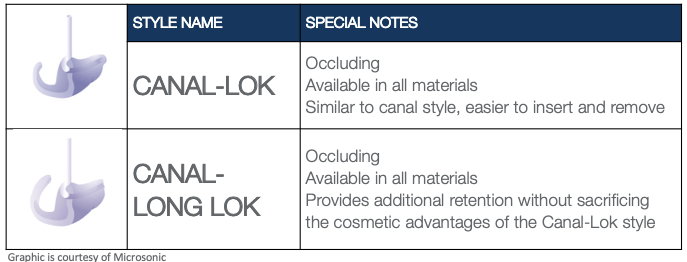

CANAL-LOK. A canal-lok may be a good choice in that case because it fits similarly to a canal mold, but it also provides enough retention to stay in the ear. There are two types of canal-loks. Whenever you are given only one choice for canal lok, ask for an extended long lok for improved retention. Typically that lok portion is not visible from outside the patient's ear. This is the reason that it is chosen for aesthetical reasons. However, a canal-lok may be tricky for first-time users because it doesn't have the full feature of the concha and helix.

Figure 5. Canal-Lok styles.

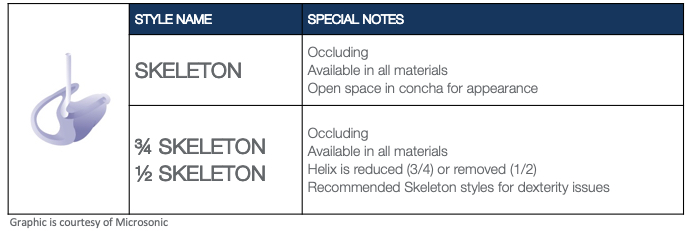

Skeleton. If appearance is still a concern, consider fitting your patient with a skeleton mold. The concha area if often in the center, so it is going to be less visible than the full shell style. The regular skeleton style may be problematic for first-time users. First-time users may have concerns about the appearance as they do not want to expose their hearing loss. Thus a skeleton mold may be a beneficial option. If the mold is difficult to insert, especially in the helix tip area, to address that issue, you can ask for a reduced helix. The manufacturer will create 3/4 or 1/2 of a skeleton so that the helix area is completely removed.

Figure 6. Skeleton style earmold.

Other Variables to Consider

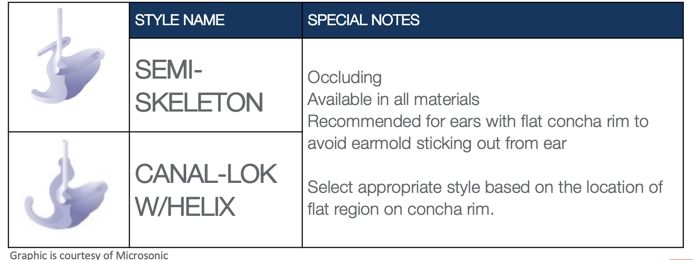

Deformed pinna. Occasionally, you will have a patient with a flat concha rim. This is more common than most providers would think. Once you take the impression, inspect the concha portion to see if the rim is flat or "razor sharp." When ordering the earmold, you can either specify a semi-skeleton style or canal-lok with a helix. Figure 7 shows how both styles look quite similar to one other. Select the most appropriate style based on the location of the flat region on the concha rim. If you cannot decide, your earmold lab will select the proper style for you.

Figure 7. Styles recommended for a flat concha rim.

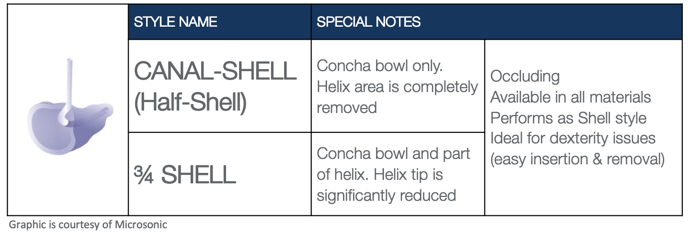

Dexterity. Another common issue is dexterity, typically due to insertion of the helix area. It may be easier to insert the canal portion, but positioning the helix may be tricky. To address this, consider styles that do not have a helix. A canal-shell (e.g., half-shell) would be our recommended style. Alternatively, you can order a 3/4 shell.

Figure 8. Styles recommended for dexterity issues.

Excessive mandibular action. Some patients may have TMJ or excessive mandibular action. The solution for this is ordering a softer material and request the manufacturer to hollow out the canal portion. By doing so, this will allow the TMJ movement and ensure the seal is never broken. Please keep in mind that this style is available in soft materials only. We can hollow out the canal portion of a shell, half shell, or even skeleton earmold styles.

Occluding earmold styles are not just for regular BTE hearing aids. They can be fit on RIC and slim tube hearing aids also. Custom earmolds are recommended for their secure fit because they offer significantly better retention over universal domes. Custom earmolds are more comfortable because they are made custom to each patient. You can fit any basic style (i.e., skeleton, canal, canal-lok, shell) and the only difference is the bore size is going to be specified for the manufacturer's receiver or slim tube.

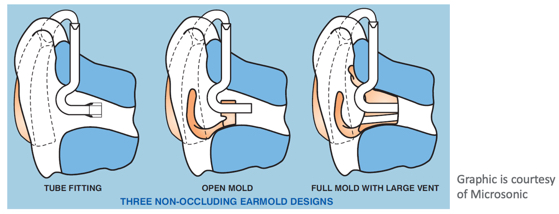

Non-occluding Earmold Styles (Open)

Non-occluding earmolds feature a small outside diameter canal portion to allow amplified sound to pass around the earmold as well as go through the tubing. This open style offers the patient a more pleasing sound by providing an overlay of amplification on the natural hearing. They are also recommended for patients who have a chronic drainage problem since aeration of the canal is allowed.

Figure 9. Non-occluding (open) earmold styles.

CROS styles. These molds are designed for CROS and many IROS fittings. Typically you would see a significant reduction in frequencies below 1000 Hz. CROS A is a canal-lok style that is slightly longer in the lok portion for retention. CROS A is made of hard materials only and has a minimum outside diameter canal. CROS B is similar to CROS A but can be ordered in both hard and soft materials. Instead of a canal-lok, we use a skeleton style. Typically the canal is shorter on a CROS B mold. CROS C is similar to CROS B except that the canal comes with extended tubing.

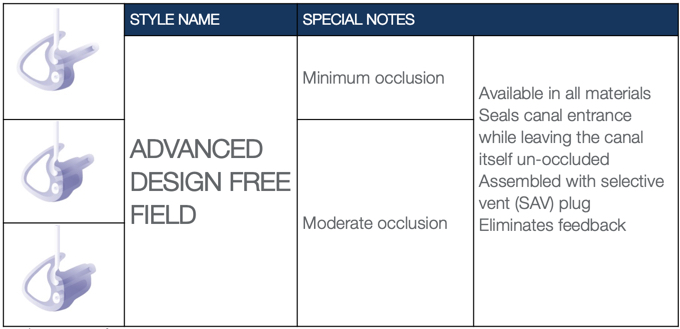

Advanced design free field. This is a very common style and comes in different canal lengths or volumes. Figure 10 show examples of these molds with minimum to moderate occlusion. These styles are available in all materials. They seal the canal entrance while leaving the canal itself un-occluded. They are assembled with a selective vent or SAV. Such an approach would eliminate feedback.

Figure 10. Advanced design free field molds.

Open-fit. IROS styles provide the largest vent possible for use with slim tubes or RIC style hearing aids. You can select SAV plugs when ordering open fit earmolds. These molds are available in all materials.

Aesthetical Considerations

Some individuals may prefer to hide their hearing impairment in their social life, and you should consider discreet options when counseling your patient. What makes an earmold discreet? The style, material, and tubing. The material of the earmold should match the skin tone of your patient. The industry offers a wide range of color options. When you place your order with the earmold lab, be as specific as you can. Another feature that can contribute to discretion is style. Keeping the patient's preference and hearing loss severity in mind, you can select the least visible style (i.e., canal-lok, skeleton, concha).

In contrast with patients who prefer discretion, there are others who choose to showcase their personal style with their hearing instruments. You can order earmolds in multiple colors, various color patterns, glitter, custom engraving of icons or shapes, the addition of stones or gems and even glow-in-the-dark materials. Such options are available in silicone, vinyl, and acrylic earmolds.

Citation

Uslu, O. (2018). Earmolds primer: custom earmolds essentials. AudiologyOnline, Article 24101. Retrieved from www.audiologyonline.com